Welcome to our case study page! Here you’ll find examples of how we have helped our clients achieve their business goals and overcome challenges. We believe in providing personalized solutions that meet the unique needs of each of our clients, and we’re proud of the results we’ve achieved.

Digitalisation of precision tube manufacturing line.

The Auto Ancilliary OEM is part of a large group of companies with 50

years of mass production experience in manufacturing cold rolled

precision tubular auto components and providing innovative tubular

solutions to their customers. Having 10 manufacturing facilities across the country, the OEM is globally recognized as a premier supplier of tubular products.

The Manufacturing line mainly comprises of following equipment and

machines which are fully automated with their own control systems in

stand alone fashion.

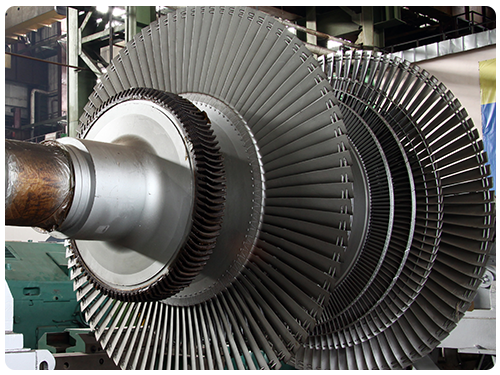

Digitalisation of Turbine Part Manufacturing Facility.

Spread over a large area, the leading OEM’s new flexible “multi modal”

factory was being set up at the outskirts of the city of Pune. The plant,

slated to manufacture different products for multiple businesses, will be

built using shared equipment, infrastructure, and manpower under the

same roof.

The manufacturer was aiming to build the facility into a “Brilliant

Factory” where all machines are connected for real time information

sharing to ensure product quality and production continuity. The aim was

also to have digitally interlinked manufacturing facility, quality

management, supply chain, distribution networks, and servicing units to

make it an intelligent ecosystem.